Laminate underlays - choose the best solution

The floor is meant to serve for many years, more and more often the warranty period for the entire floor system is a quarter of a century. However, each warranty has its limitations. As it is worth noting, the warranty applies to the entire system - both the panels and the underlay. The underlay for panels is an important element of the new floor, which significantly affects its durability.

Form: Roll

Technology: PU+minerals+ PET

Thickness: 1.5 mm

Form: Smart

Technology: XPS/PET

Thickness: 5 mm

Form: Smart

Technology: XPS/PET

Thickness: 3 mm

Form: Roll

Technology: PU+minerals+ PET

Thickness: 2 mm

Form: Roll

Technology: PU+minerals+ PET

Thickness: 3 mm

Form: Roll

Technology: PEHD/PET

Thickness: 2 mm

Form: Roll

Technology: PEHD/PET

Thickness: 1.5 mm

Form: Roll

Technology: PEHD/PET

Thickness: 2 mm

Form: Roll

Technology: PEHD

Thickness: 2 mm

Form: Smart

Technology: XPS/PET

Thickness: 2.2 mm

Form: Smart

Technology: XPS/PET

Thickness: 5 mm

Form: Roll

Technology: XPS/PET

Thickness: 2 mm

Form: Roll

Technology: XPS

Thickness: 2 mm

Form: Roll

Technology: XPS/PET

Thickness: 1.6 mm

Form: Roll

Technology: XPS

Thickness: 1.6 mm

Form: Roll

Technology: XPS

Thickness: 1.6 mm

Form: Smart

Technology: XPS/PET

Thickness: 1.6 mm

Form: Roll

Technology: M-BASE - Mineral Base Underlay

Thickness: 2.0 mm

So what should you remember to ensure the durability of the floor, and peace of mind and confidence that the terms of the warranty are met? First of all, you need to read the instructions included in the package with the floor and strictly follow the installation rules contained therein. However, there are features common to floors made in the same technology. Laminated panels, based on the construction of an MDF or HDF core with a click assembly, have many advantages such as quick installation, relatively low weight, faithfully reproducing the structure of wood or stone, and most importantly, they are available at very attractive prices.

All these advantages, however, are accompanied by disadvantages caused by the construction of the panels themselves. Laminate panels are noisy in use especially the sounds reflected from the surface are deaf and irritating. The second thing to note is water sensitivity. Due to the specific structure, even a short-term contact of the core of the panels with water causes irreversible damage to it. Can you fight it? Yes, these negative values that the construction of laminate panels entails can be significantly reduced by using an appropriate underlay. However, before we lay the underlay for laminated panels, we should take care of the subfloor.

Subfloor under the Laminate underlay

The floor must be laid on a stable and levelled surface, the deviation of which may not exceed 2 mm by 200 cm in length. The subfloor for laminate flooring must be dry, clean and load-bearing. As laminates are very sensitive to moisture, it is worth checking the moisture content of the substrate with the CM chemical carbide meter. The moisture content of the cement subfloor without underfloor heating system, must not exceed 2% CM, and the moisture content of the anhydrite subfloor 0.5% CM. In the case of installed underfloor heating, the above values must not exceed 1.8% CM and 0.3% CM respectively.

Thousands of litres of water are used to build a house, which are often found in ceilings and walls. Moisture from the air can also increase the humidity of the floor, therefore, before laying the floor, ensure the appropriate temperature in the room (18-23 degrees) and control its relative humidity (50-70%). Accurate measurement is extremely important especially when the time of investment implementation has significantly shortened and the pressure on quick execution is growing. The rule is simple: the subfloor must dry out.

How to protect panels from moisture

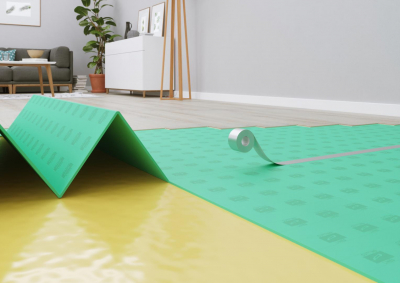

Before laying the panels on a mineral (cement or anhydrite) substrate, first install a suitable vapor-proof insulation to protect against moisture. Vapor barriers should also be used when installing panels over water underfloor heating.

The function of this layer is to permanently protect against moisture from the ground. The vapor barrier can be a special vapor barrier foil or an underlay with an integrated vapor barrier. When choosing a vapor barrier foil, its thickness should not be taken into account but rather the SD coefficient - the higher its value, the better the floor is protected against the effects of moisture. The minimum required value for this factor is SD> 75 m.

On the prepared substrate, a vapor barrier foil should be spread over an overlap of 20-30 cm and glued with a moisture-resistant tape. The foil must be turned onto the walls to a height of 3-4 cm.

A faster and more reliable alternative is the use of underlays with an integrated vapor barrier foil (in Arbiton products this technology is called Aquastop) in the 2-in-1 version (i.e. the underlay and the foil joined together) or 3-in-1, which, apart from the integrated vapor barrier foil, also have a self-adhesive tape that facilitates joining the underlay. 3-in-1 underlays in the version with an easily unfolded accordion are up to 5 times faster to install than a regular board. This is where the Secura Aquastop series underlays triumph on the European market, thanks to a wide range, Secura XPS technology is the most common choice among DIY store customers.

How to mute a floor with instaled laminate panels

We will protect the panels against moisture, it would also be good to reduce the noises. If we want to soundproof the floor, we must distinguish between two types of parameters related to it. Underlayment for the panels can mute the floor by reducing the sounds reflected from the surface - this is what the RWS (Reflected Walking Sound) parameter tells us about. The second important parameter is IS (Impact sound) which tells us about muffling sounds that pass through the ceiling. Invaluable support in soundproofing the attic floor or isolating our noises for the neighbour below us.

Very good parameters for the IS soundproofing can be obtained by using XPS underlays from the Secura family- up to the level of 22dB. However, if you are looking for products with uncompromising parameters, you should choose polyurethane underlayment with minerals from the range of Multiptotec. These are the highest quality products and the best parameters on the market. For example, the Multiprotec Absolut equals to 30% RWS - that is, damping of steps reflected from the floor and 21dB in the case of IS.

Let's protect the locks

Well-chosen and properly installed underlays under the floor extend its durability and increase the comfort of use. They help to soundproof the panels and effectively protect their locks against mechanical damage.

Panel manufacturers require a stable and levelled subfloor. The underlay cannot compensate for the differences in floor levels, however, point unevenness of the floor, i.e. not too large, spot irregularities, can be levelled with the use of appropriate underlays. Underlays are able to absorb, for example, small particles of screed, thanks to which the surface of the underlay becomes smooth and panels can be laid on it. This parameter is marked as PC and its value is expressed in mm. The thickest underlays can compensate for point unevenness up to 5mm.

If we lay the floor in an intensively used room, we want to provide the floor with the greatest possible stability and durability. A suitable underlay, with the highest possible load resistance factor, will perfectly absorb the floor and provide protection for delicate panel locks. The load resistance parameter is denoted as CS and its value is expressed in kPa.

To sum up, a good underlay is able to significantly improve the performance of even worse-quality laminate flooring, and if we care about the durability and comfort of using laminate panels, the underlay should be treated as a starting point and foundation of good system.

Polski

Polski

English

English

Deutsch

Deutsch

Italiano

Italiano

Svenska

Svenska

Čeština

Čeština

Română

Română

Русский

Русский

Українська

Українська

Slovenčina

Slovenčina

Español

Español

Français

Français

Magyar

Magyar

Nederlands

Nederlands