Vinyl click flooring underlays, dedicated solutions

If you have decided to buy vinyl flooring, pay special attention to the underlay. The underlay is an invisible element hidden under the panel, but as when building a house, it is the foundation of the entire floor. The underlay for vinyl flooring has a protective function for the entire flooring.

Form: Roll

Technology: Pu + minerals

Thickness: 1.4 mm

Form: Smart

Technology: Modified xps/pet + foil overlap

Thickness: 1.5 mm

Form: Roll

Technology: PU+minerals+ PET

Thickness: 2.2 mm

Form: Roll

Technology: M-BASE - Mineral Base Underlay

Thickness: 1.3 mm

Form: Smart

Technology: MODIFIZIERTE XPS + PET

Thickness: 1 mm

Form: Smart

Technology: Modified xps/pet + antislip layer + foil overlap

Thickness: 1.5 mm

Form: Roll

Technology: PU+minerals+ PET

Thickness: 1.1 mm

Form: Roll

Technology:

Thickness: 0.18 mm

Form: Platte

Technology: XPS

Thickness: 5 mm

Form: Smart

Technology: MODIFIZIERTE XPS + PET

Thickness: 1 mm

Form: Roll

Technology:

Thickness: 0.18 mm

Due to the appropriate hardness and flexibility, it protects the floor against micro-damage. Using more down-to-earth analogies, the underlay acts as a shock absorber that protects our entire floor. Without it, particularly sensitive areas such as panel locking systems can quickly deteriorate. It is worth choosing floor underlays from proven European producers because they are a guarantee of quality. An invisible and inconspicuous underlay for vinyl planks is an element that can make our vinyl planks look beautiful longer, or on the contrary - they will be damaged quickly. Therefore, when choosing a floor underlay, you should not compromise and focus on quality and proven properties.

Click vinyl floors require an underlay

More and more vinyl planks are sold to be installed in the known floating system. This means that the panels are joined together by means of locks without being permanently attached to the ground. The "click" system, also known as "floating", is an excellent choice when you want to lay the floor yourself. If you have a regular developer screed that is never ultra-smooth, click vinyl will also be a good choice. They will also prove useful during renovation and when we want quick, effective results. In the floating system, the panels are connected thanks to locks. There are different mounting systems - 2G, 5G or fall down locks, e.g. 5Gi. The 5G lock is the latest patented system by the Swedish company Valinge. The panels are connected in this system by inserting the long side of the board into the lock profile and lowering it downwards. When two panels are properly connected, they will give the characteristic sound of the so-called click. 2G type locks, which have been proven for years, are also very good.

The connection in this type of panels is mechanical - precisely milled elements interlock to create a durable, secure connection that protects against forces acting in all directions. The assembly does not require any tools, and you do not hit the locks with a hammer. Regardless of the type of connection, vinyl click flooring locks, due to the precise milling, are the element most exposed to damage. Therefore, in order to protect them, we must choose a floor underlay that will provide a stable and durable substrate that will take all the stresses and protect the panels at the same time.

Compressive strength - a parameter of the underlay that you must remember

Before introduced to the market, floor underlays must undergo dozens of tests to determine their quality and objective parameters. Good manufacturers of underlays are fine to present the results of these tests. Thanks to this, customers can precisely determine which underlay will better meet their expectations.

There are several parameters that determine the quality, durability and resistance of the underlay. The key parameter of underlay important for vinyl panels is the CS (compressive strength). This is the factor that determines how our underlay withstands static loads. Its value is expressed in kPa. It is assumed that an underlay suitable for vinyl click planks should have a minimum value of 200 kPa, but the recommended value is 400 kPa. The higher the CS coefficient, the better the underlay withstands heavy loads and absorbs them. Thanks to this, it protects the delicate panel locks against damage.

It is also worth paying attention to the kneading resistance, i.e. DL, which tells us about the dynamic load. The test consists in applying pressure on the underlay cyclically with equal force. When the underlay is compacted by 0.5 mm under the influence of the force, the test is interrupted and the number of cycles that the flooring system has withstood determines its resistance. According to the standard, it should be more than 10,000. cycles.

The most spectacular test of floor systems is the so-called chair test (castor chair test). It is the most demanding test that determines the durability of the entire floor system - underlays together with vinyl flooring. It is used to test the parameters of materials during the simulation of real use. What does such a test look like? A sample defined by the standard is prepared - a panel, base and carrier material. A specially constructed machine consisting of a rotating platform to which a sample is attached and then a weight of 90 kg is applied through wheels of the appropriate type. The platform makes thousands of rotations, changing the direction of rotation every 60 cycles. In order to obtain a result that allows the sample to be assigned a utility class of at least 32, the tested elements must withstand as many as 25,000 cycles.

It is because of the rigorous tests that a vinyl floor has to cope with that an appropriate underlay becomes so important. Therefore, the popular polyethylene PE foam is absolutely not suitable for vinyl click flooting. Also underlays dedicated for laminate floor will be suitable.

Fire resistance for floor underlays

If we are finishing a commercial facility, the fire resistance class will be parameter of an extremely importance. When testing and determining the fire resistance of a floor system, the weakest link in the system is taken into account. As a rule, vinyl planks have the BFL fire resistance class - and are therefore completely non-flammable. Polyurethane-mineral underlays that can boast of this class. For commercial investments, we should look for underlays with the BFL S1 class. Other underlays are EFL-rated - so they do not burn spontaneously, but can sustain a fire.

PUM perfect for vinyl flooring

When it comes to underfloor heating system vinyl flooring are the most frequently chosen material, apart from stoneware. These relatively thin panels perfectly conduct heat and are therefore recommended for underfloor heating. However, we must remember that when we install vinyl click flooring, their thermal conductivity will depend not only on the parameters of the panel itself, but also on the underlay we choose for it. Only the best underlay will ensure the comfort of using underfloor heating. A good underlay is a guarantee of a quiet, safe and effective floor in terms of underfloor heating. Therefore, it is not allowed to save on floor underlays. Underlays dedicated to underfloor heating are characterized by a very low coefficient of thermal resistance. This means that by heating the house we can save a lot of money.

It is the underlay that determines whether the panels will perform as good as the manufacturer promises. A good underlay for vinyl flooring can cost up to EUR 7 / m2. Is it worth investing so much? PUM (polyurethane-mineral) underlays are available on the market. They are more resistant to pressure (in form of the roll, they have a very large weight), thanks to which they protect the floor, but above all, thanks to a very low index of thermal resistance, they are ideal for underfloor heating.

The parameter we are interested in in this case is R - thermal resistance. If we have underfloor heating installed, we must reach for an underlay dedicated to such a solution. PUM (polyurethane-mineral) underlays are ideal for underfloor heating. The best of them have a thermal resistance of R-0.006 m2 K / W. The decision to choose a floor underlay is very important. Its properties determine not only the longevity of our floor, but also thermal and acoustic comfort.

Which vinyl backing should you choose?

As a rule, when choosing underlay, we should be guided by technical data, and if their interpretation is difficult for us, choose a product of a good manufacturer. European producers and brands such as Arbiton guarantee that the underlay will meet the standards presented on the packaging. You should be very careful with products that are not tested and their properties are only declarative and have little to do with reality. Vinyl click flooring are thin products with precisely milled locks. Therefore, they require a dedicated underlay that will not only provide acoustic comfort, but also increase the efficiency of underfloor heating and effectively protect the locks of vinyl flooring panels.

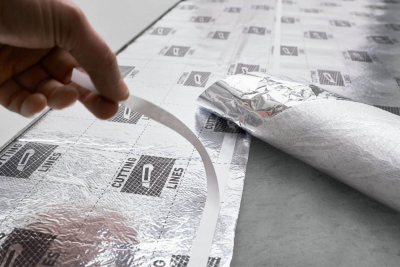

A very good choice for vinyl floors are PUM underlays (polyurethane with minerals), they can be dedicated to underfloor heating, which, thanks to a very low thermal resistance coefficient, realistically reduce the costs associated with heating the house. Such a purchase is returned to us after a few heating seasons, not to mention the faster heating up time of the room. For vinyl flooring, we should look for dedicated underlays, which are often additionally marked as 'Vinyl'. The offer of recognized producers includes underlays with the 3-in-1 system (underlay, foil, tape). These three elements are integrated, making the installation of the underlay child's play.

Recently, the PUM underlay has been widely available - which, thanks to its above-average hardness (CS even up to 550 kPa), allows you to install a new vinyl click floor directly on old tiles, the joints of which are of standard width. The most resistant products have CS at the high level and DL is very high as well. Such underlay can be found in the Arbiton brand under the name Multiprotec Hardlay. It is a underlay that is dedicated especially to the latest generation vinyl click flooring- SPC / RIGID.

Laying vinyl flooring on ceramic tiles

Some underlays are labeled "Antislip". This means that the underlay is equipped with a thin layer of glue. It is meant to additionally support the stability of the floor system by preventing the panels from sliding on the underlay surface. It is up to the manufacturer to determine if the panel needs underlay with antyslip layer or not. Therefore, before buying an underlay check the manufacturer's recommendations for our panels.

And if we care about ecology, choose foundations with the Blue Angel sign. Three Arbiton underlays for vinyl flooring (Multiprotec Vinyl Click Antislip, Multiprotec Vinyl Click and Multiprotec Vinyl Click Hardlay) have received this most important and the oldest certificate for the world ecology. When qualifying products, the following factors are assessed: saving of raw materials, reducing the amount of pollution, reducing noise, eliminating or reducing the amount of waste and the possibility of reusing it. Blue Angel is a signal informing the consumer that a given product is safer than other products of the same type. Underlays with the Blue Angel label have an extremely low emission level, ensuring a healthy indoor climate.

Which underlays for vinyl planks should be avoided?

First of all, those from unknown producers. The market is flooded with floor underlays imported from East, the properties of which do not meet absolutely any standards. They do not have technical data sheets for products and their use may not only damage our panels, but also seriously harm us legally (e.g. in the case of construction of commercial buildings). In addition, in the event of damage to the floor, the manufacturer's warranty will not protect us. That is why we should choose foundations of well-known, reputable European brands.

Secondly, you should absolutely beware of products that offer a panel with an integrated underlay and underlays made of PE foam. The 2-in-1 panels with a glued underlay appearing on the market are only seemingly comfortable. We are tempted by the ease of assembly. In fact, we get a medium-quality vinyl plank and a very poor underlay. Panels with an integrated underlay also do not provide adequate stability for the entire floor. The underlay does not protect the most sensitive elements of the vinyl flooring panels - the locks – very often it is not placed under the locks. The underlay transmits the force and distributes it over a larger area. If the underlay glued under the panel does not dissipate any force, all loads are compounded and damage to the floor is much easier. The offered underlays integrated with the panels are of very poor quality.

Vinyl flooring on IXPE foam underlayment - visible damage to the locks and lifting of the panel after only 20 months of use.

Does the underlay have to be of the same brand as the vinyl flooring?

Very often, when choosing floor panels, we decide to buy an underlay from the same manufacturer. This is a shortcut that mainly sellers propose to us. Because sometimes manufacturers make the validity of the warranty dependent on whether we use an underlay and, for example, floor accessories from one supplier. However, it is worth knowing that it is not legally possible to exclude the warranty due to the use of a underlay from another manufacturer. Of course, it must meet the standards set by the manufacturer of vinyl flooring. As a rule, it is worth choosing vinyl planks from a company that is also a manufacturer of underlays. This means that a given manufacturer specializes in the production of floor systems, and spends a lot of time and energy on testing and improving its products. If we are dealing with a distributor, it will rather recommend a low-quality underlay, on which it has the highest margin. We should trust experts in specialized, independent stores or compare the properties of the underlays ourselves and follow objective criteria when choosing.

Good underlay for vinyl flooring

A good underlay is just as important as the material from which the floor is made. This element should not be underestimated just because it is invisible. Floor underlays do a huge job, thanks to which we can enjoy not only a beautiful floor for many years, but also reduce heating bills in real terms or enjoy the silence of the home. And what are the costs of underlays? The cheapest underlays for vinyl flooring, which will fulfil their role and constitute a kind of compromise between quality and cost, cost about EUR 3-4 / m2 (i.e. Afirmax Vinyl Smart). The best products are the discussed polyurethane-mineral underlays, i.e. Arbiton Multiprotec Vinyl Click. We then have to take into account the cost of EUR 6-7 / m2, but we have an absolute guarantee of quality.

There are many good underlays and they can be made in various technologies. The most important thing is that the underlay should be adapted to our needs.

Polski

Polski

English

English

Deutsch

Deutsch

Italiano

Italiano

Svenska

Svenska

Čeština

Čeština

Română

Română

Русский

Русский

Українська

Українська

Slovenčina

Slovenčina

Español

Español

Français

Français

Magyar

Magyar

Nederlands

Nederlands